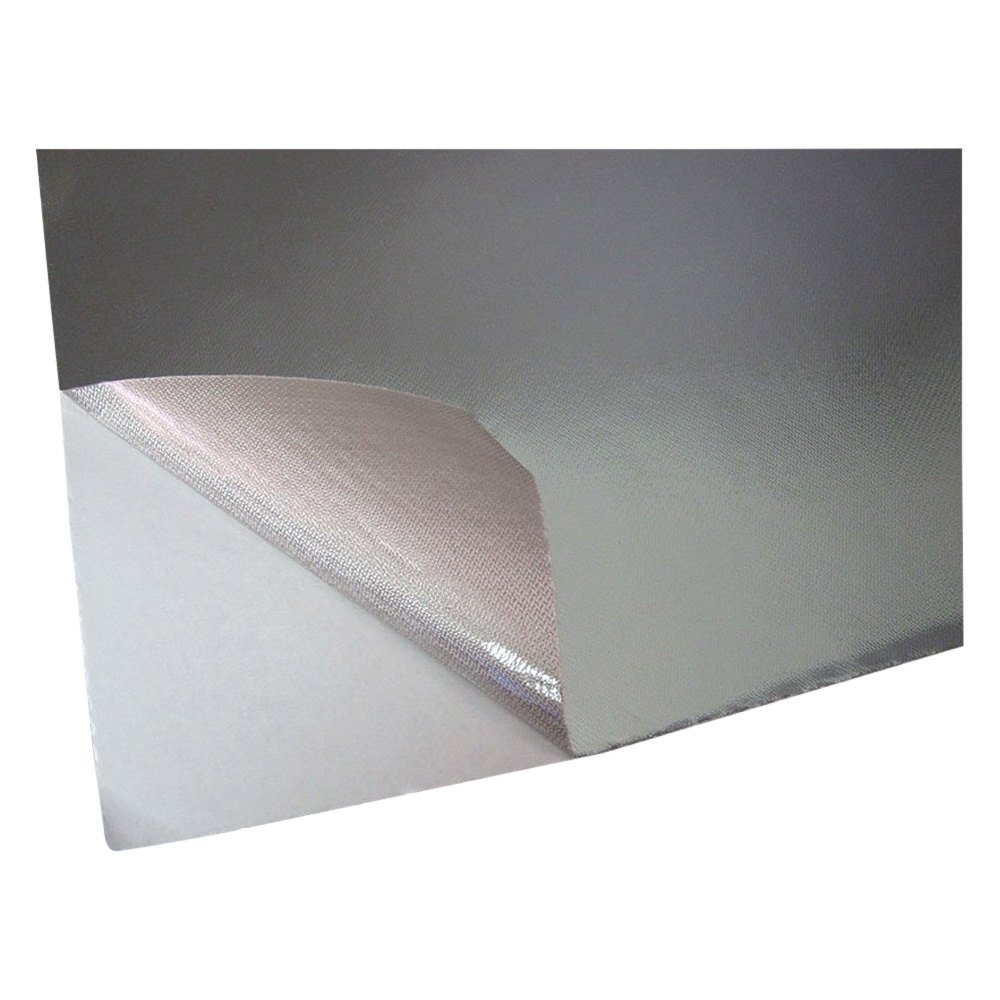

Adhesive-Backed Heat Shielding represents a revolutionary leap in thermal management technology, offering a uniquely versatile and user-friendly solution to a pervasive problem across countless industries: controlling and reflecting radiant heat. At its most fundamental level, it is a composite material engineered for performance and simplicity. The core of this shield is a robust fiberglass substrate, a material chosen for its inherent thermal stability and durability. This substrate is then aluminized, meaning it is coated with a highly reflective layer of aluminum. This aluminum surface is the primary actor in heat shielding, as it works to reflect radiant heat energy away from the protected component or surface, rather than absorbing it. This principle of reflection is far more efficient than simple insulation at managing radiant heat, which is the type of heat you feel when you stand near a hot engine or an oven.

The defining characteristic that separates this product from traditional heat shields is its full, pressure-sensitive acrylic adhesive backing. This entire rear surface is a strong, heat-resistant adhesive, pre-applied at the factory for immediate use. To protect this adhesive until the moment of application, it is covered by a silicone-coated paper release liner. This simple feature is what unlocks the product's incredible customizability and ease of installation. Unlike rigid metal shields that require brackets, drilling, or welding, or bulk insulation that needs to be sewn or wired into place, adhesive-backed heat shielding can be applied directly and permanently in a matter of minutes.

The process of customization is intentionally democratized. There is no need for specialized tools, metal shears, or fabrication shops. The material is pliable yet tough, and it can be precisely cut to any conceivable shape or size using a tool as common and accessible as a standard pair of household scissors. This allows a user to create complex templates, fit the shield into tight, awkward spaces, or contour it around curves and protrusions with an exactitude that is impossible with pre-formed shields. A standard piece is offered in a practical 12-inch by 36-inch sheet, providing ample material for multiple small projects or a single large application, with manufacturers often willing to produce custom rolls or sheets for industrial-scale needs.

The performance specifications of this material are where its engineering excellence truly shines. It is designed to operate reliably in a continuous ambient temperature range from a frigid -40°F to a high of 356°F (-40°C to 180°C). This makes it suitable for environments that experience wide temperature swings, such as an automobile engine bay. More impressively, it can survive short-duration, high-intensity "flash" exposures up to a blistering 995°F (535°C). This is critical for deflecting heat from exhaust manifold pulses or other brief, extreme thermal events without delaminating or degrading.

Installation, while simple, follows a critical three-step process to ensure a permanent, bubble-free bond. First, surface preparation is paramount. The target surface must be meticulously cleaned of all oil, grease, dust, and moisture using a appropriate cleaner. Any residue will compromise the adhesive's bond, leading to failure. Second, the shield should be measured and pre-cut to its final shape before the release liner is ever peeled. This allows for dry-fitting and adjustments without exposing the adhesive to contaminants. Finally, the application itself should be a controlled, deliberate process. Starting from one corner or edge, the release liner is peeled back, and the shield is gradually applied to the surface, using a hand or a soft roller to smooth it out from the center toward the edges. This technique pushes out air pockets and prevents wrinkles, ensuring a flawless, professional-looking finish that maximizes thermal contact and reflective efficiency.

In essence, Adhesive-Backed Heat Shielding is more than just a product; it is a system. It integrates the high-performance reflective qualities of aluminized fiberglass with the unparalleled application convenience of a full-coverage, strong adhesive. This synergy creates a heat management solution that is as effective at protecting a vehicle's wiring loom as it is at safeguarding a kitchen wall, making advanced thermal protection accessible to professionals and DIY enthusiasts alike.