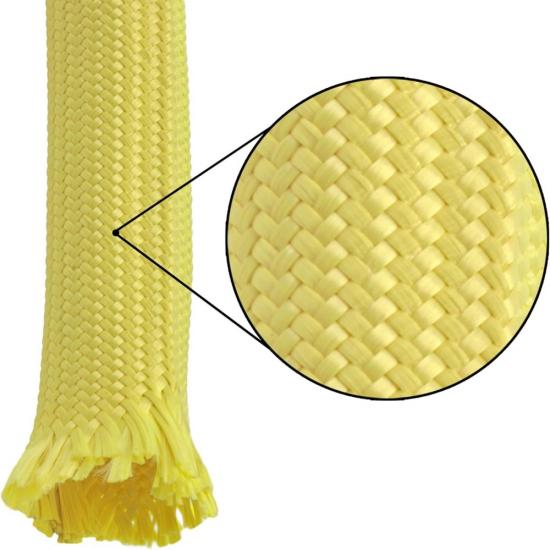

Braided Aramid Sleeve – High-Strength Abrasion Protection for Industrial Hoses & Cables

The braided aramid sleeve is a high-performance protective sleeving engineered for applications where abrasion, cutting, and mechanical wear are the primary causes of hose and cable failure. Unlike standard PET or nylon sleeves, aramid fiber construction delivers exceptional strength and durability in aggressive industrial environments.

This product is widely used to protect hydraulic hoses, pneumatic lines, cable harnesses, and wiring systems exposed to constant movement, vibration, and contact with sharp surfaces.

Why Choose a Braided Aramid Sleeve Instead of Standard Sleeving?

In many industrial applications, hose and cable damage is not caused by pressure or temperature, but by external mechanical stress. Conventional textile sleeves often wear through quickly, leaving critical lines exposed.

A braided aramid sleeve is designed specifically to solve this problem by offering:

-

Extremely high abrasion resistance

-

Outstanding cut and tear strength

-

Long service life under continuous movement

-

Lightweight protection without reducing flexibility

This makes it an ideal solution for demanding environments where downtime is costly and safety is critical.

Material & Construction

BST braided aramid sleeves are manufactured from high-tenacity aramid fibers using a dense braided structure.

Material characteristics include:

-

Very high tensile strength

-

Low elongation under load

-

Excellent resistance to cutting and tearing

-

Stable performance under vibration and repeated flexing

The braided construction allows the sleeve to expand and conform to hoses and cables while maintaining consistent coverage and protection.

Key Performance Benefits

Superior Abrasion Resistance

Aramid fibers significantly outperform PET and nylon in abrasive environments. The sleeve protects hoses and cables from continuous rubbing against metal frames, brackets, guide rails, and surrounding equipment.

Cut & Impact Protection

The dense braid structure resists damage from sharp edges, debris, and accidental tool contact, helping prevent sudden hose or cable failure.

Flexibility for Dynamic Applications

Despite its strength, the braided aramid sleeve remains flexible, allowing full movement in applications involving bending, articulation, or vibration.

Lightweight & Non-Conductive

The sleeve adds minimal weight and is electrically non-conductive, making it suitable for both fluid lines and electrical systems.

Typical Applications

The braided aramid sleeve is commonly used in industries where mechanical wear is unavoidable:

-

Mining Equipment – excavators, loaders, drilling rigs

-

Underground Mining – LHD machines, hydraulic systems

-

Robotics & Automation – robotic arms, cable carriers

-

Industrial Machinery – moving hoses and wire bundles

-

Construction Equipment – heavy-duty mobile hydraulics

-

Automotive & Motorsport – vibration-intensive zones

Anywhere abrasion, vibration, or cutting is a concern, a braided aramid sleeve provides reliable protection.

Installation & Handling

BST braided aramid sleeves are designed for easy integration:

-

Slide-over installation

-

Can be cut to length without excessive fraying

-

No adhesives or curing required

-

Compatible with clamps, ties, or heat-shrink terminations

Suitable for both OEM assembly and field retrofitting.

Operational Value

By protecting hoses and cables from external damage, braided aramid sleeves help:

-

Extend service life of critical components

-

Reduce unplanned downtime

-

Lower maintenance and replacement costs

-

Improve overall equipment reliability

In many cases, preventing just one hose failure offsets the cost of sleeving.

Why Buy Braided Aramid Sleeves from BST

At BST Braided Sleeve, we specialize in industrial protective sleeving solutions engineered for real-world operating conditions.

Our advantages include:

-

Consistent quality control

-

Industrial-grade aramid materials

-

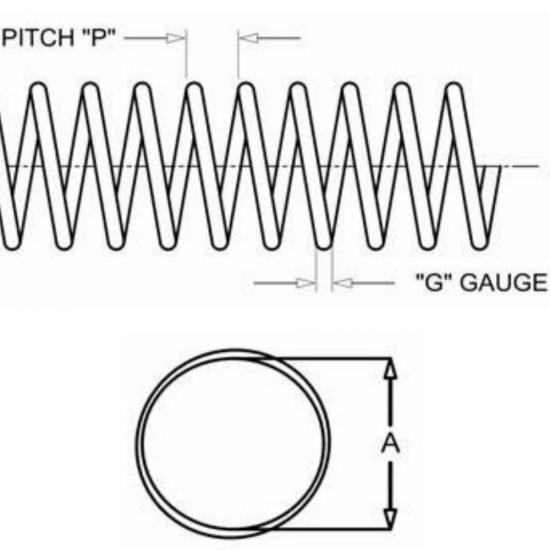

Custom diameters and lengths available

-

Reliable supply for OEM and aftermarket needs

We work closely with customers to ensure the right protection solution for each application.

The braided aramid sleeve is a proven solution for protecting hoses and cables against abrasion, cutting, and mechanical damage. Designed for harsh industrial environments, it delivers long-term durability without sacrificing flexibility or ease of installation.

For industries where mechanical wear is the leading cause of failure, braided aramid sleeves provide dependable, cost-effective protection.