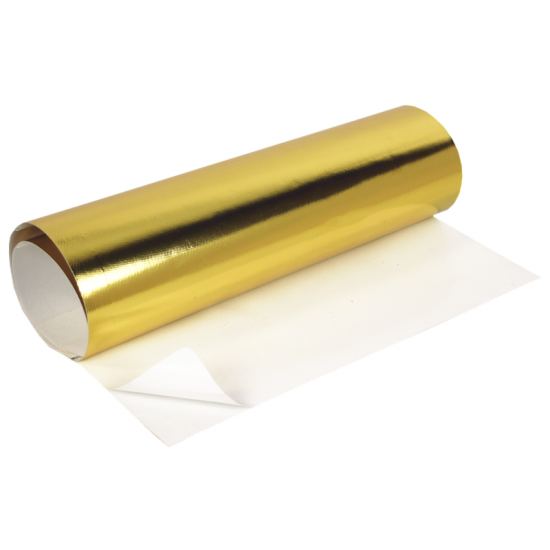

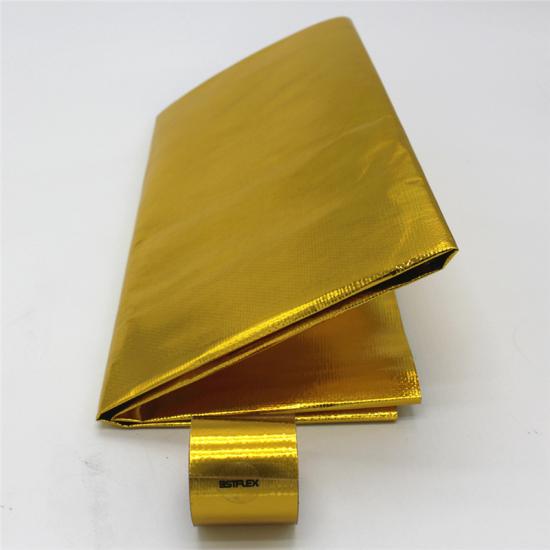

Thermal Shield Adhesive Backed Gold Heat Reflective Sheet

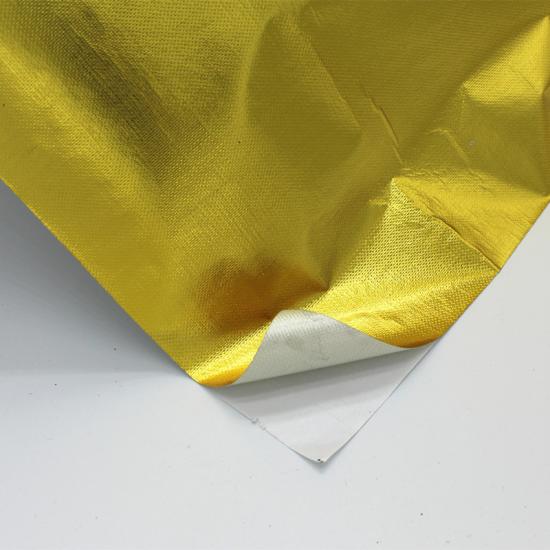

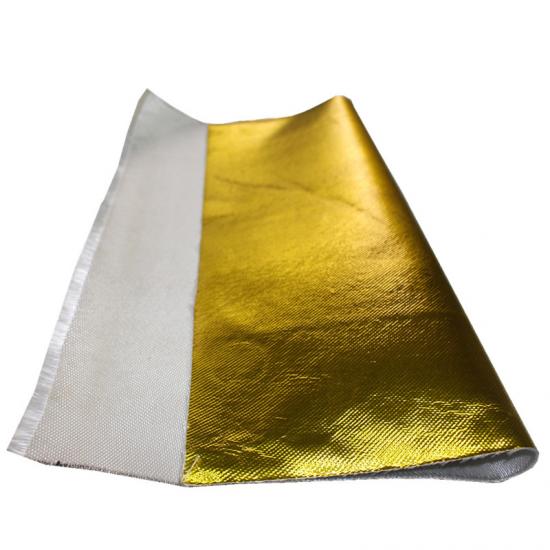

Thermal Shield Adhesive Backed Gold Heat Reflective Sheet is a peel-and-stick radiant heat barrier designed for under-hood panels and compact thermal zones where installation speed and stable reflection matter. It is constructed from a metallized polyimide (gold reflective face) laminated to lightweight fiberglass cloth, and finished with a high-temperature pressure-sensitive adhesive (PSA) backing.

The gold reflective face is engineered to reduce radiant heat soak on nearby panels and components, supporting more stable temperatures in engine bays, firewalls, and bulkheads.

Key Performance

- Radiant heat reflection: up to 90% (gold face toward the heat source)

- Radiant Heat Resistance: 800°F

- Adhesive Heat Resistance: 325°F

- Temperature swing capability: designed for extreme temperature-swing environments

- Durability: UV resistant for long-term performance

- Application efficiency: self-adhesive backing enables fast installation on properly prepared surfaces

Typical Applications

Used where radiant heat causes heat soak on panels and nearby components, including:

- Firewalls and bulkheads

- Under-hood panels and engine compartments

- Fuel-cell and heat-sensitive compartment areas

- Engine covers and seat-bottom areas

- Localized hot zones requiring a thin reflective barrier

Installation Guidelines

- Surface preparation: Clean the mounting surface thoroughly. Remove oil, dust, moisture, and loose coatings. The substrate must be clean and dry.

- Fit and cut: Test-fit before removing the release liner. Cut with a sharp blade and round corners to reduce edge lift.

- Apply with pressure: Peel the liner gradually and press firmly from the center outward to avoid trapped air. A roller is recommended for larger areas.

- Orientation: Install with the reflective gold face toward the radiant heat source.

- Edge management: In high-vibration or splash zones, reinforce critical edges with edge sealing or mechanical retention as required by the assembly.

Failure Modes & Risk Control

1) Edge lift / corner peel

- Failure mode: Edges begin lifting and can progress into peeling.

- Root causes: Sharp corners, inadequate pressure during application, vibration, airflow at leading edges, contamination at edges.

- Risk control: Radius corners, apply firm pressure/rolling, avoid exposed leading edges where possible, add edge sealing or mechanical retention in severe vibration zones.

2) Adhesive softening / debonding under heat

- Failure mode: Adhesion weakens after heat exposure; the sheet shifts or releases.

- Root causes: Bond-line temperature exceeds the adhesive rating (325°F), heat source too close, insufficient airflow, hot substrate.

- Risk control: Keep the mounting surface within the adhesive rating, increase clearance or introduce an air gap, improve airflow, or use mechanical retention where bond-line temperatures cannot be controlled.

3) Oil / coolant / chemical contamination

- Failure mode: Local lifting or progressive peel, typically starting at edges.

- Root causes: Residual oil/grease, coolant residue, aggressive cleaning chemicals, ongoing fluid splash.

- Risk control: Degrease and dry the surface before installation, avoid applying over uncured coatings or residues, protect edges in splash-prone areas, verify chemical compatibility if routine solvent cleaning is expected.

4) Blistering from trapped air

- Failure mode: Bubbles reduce contact area and initiate lift.

- Root causes: Fast application without pressure, rough/dirty substrate, low installation temperature reducing adhesive wet-out.

- Risk control: Apply gradually, press/roll from center outward, install at a practical ambient temperature, ensure the substrate is smooth and clean.

5) Abrasion / scuffing of the reflective face

- Failure mode: Surface damage reduces reflective performance over time.

- Root causes: Contact with hoses/wiring, service abrasion, vibration-driven rubbing.

- Risk control: Maintain clearance to moving parts, secure adjacent harnesses/hoses, avoid placement where routine maintenance contact is unavoidable.

RFQ (Request for Quote)

To quote accurately and confirm fit for your thermal zone, please include:

- Application location: firewall / bulkhead / under-hood panel / engine cover / other

- Heat source: turbo / manifold / downpipe / exhaust pipe / other, and approximate clearance (mm/in)

- Exposure type: primarily radiant heat (line-of-sight)

- Peak temperatures and duty cycle: continuous or intermittent

- Mounting substrate: aluminum / steel / coated panel / composite (specify coating if known)

- Fluid exposure: oil / coolant / fuel / water splash (yes/no)

- Vibration level: low / medium / high

- Size requirement: choose a part number or provide L × W

- Quantity: prototype quantity and monthly volume if applicable

-

Format preference: sheet / custom cut / die-cut parts (template file if available)

Download Technical Overview: Adhesive Backed Gold Heat Reflective Sheet (PDF)