Summary: Understand the difference between I.D. and O.D., how to measure hoses and bundles, and how to select sleeve I.D. using practical oversize rules. Includes circumference-to-diameter formula, an RFQ-ready sizing checklist, and installation tips.

Hose and cable protection near heat/flame: Fire Sleeve | Localized hot spot shielding: Heat Shield Tape | Turbo/exhaust heat management: Exhaust Insulation Solutions | Technical PDFs: Download Technical Documents

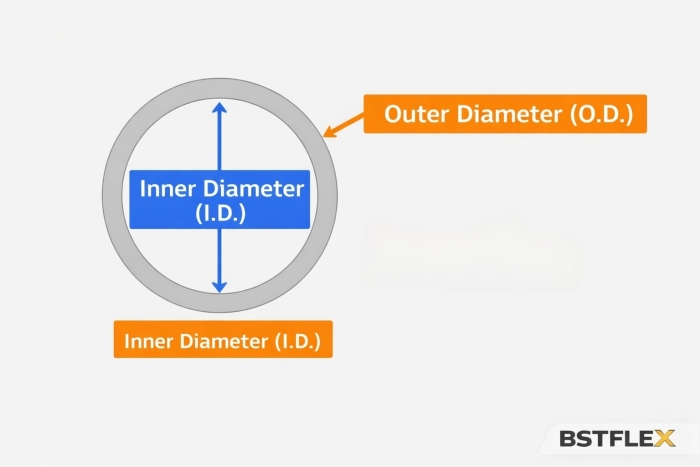

This diagram explains I.D. and O.D. at a glance. For most sleeving applications, remember: Sleeve sizing uses hose I.D.

If your hose is routed close to hot exhaust components, correct sizing is only one part of reliability. Consider reducing heat at the source using exhaust insulation solutions, then protect hoses/wiring with fire sleeve protection.

Use the formulas below to convert measurements and select an appropriate sleeve size for hoses and bundles. This is a practical engineering reference for quick sizing checks.

If you can only measure circumference (C), convert it to diameter (D):

Example: C = 160 mm → D ≈ 160 ÷ 3.14 ≈ 51 mm.

Sleeves are typically specified by sleeve I.D., but selection should start from the hose/bundle O.D.. Use these quick guidelines:

Example: Bundle O.D. = 50 mm.

To confirm sleeve size quickly and avoid back-and-forth, you can copy the checklist below into your RFQ. If you can provide photos of the routing area, we can verify clearance, contact risk, and fastening points.

If the routing is close to turbo or exhaust components, we often recommend a combined solution: reduce heat at the source using exhaust insulation solutions, then protect hoses/wiring with fire sleeve. For localized edge protection and reinforcement, consider heat shield tapes and barriers.

I.D. is the measurement across the inside opening of a tube or sleeve. It describes the internal clearance available inside the product.

O.D. is the measurement across the outside of a tube, hose, or sleeve. For protective sleeving, the hose/bundle O.D. is usually the key sizing reference because it reflects the installed diameter.

In most cases, size sleeves based on the hose or bundle O.D. (installation diameter), not the hose I.D. (flow diameter). Choose sleeve I.D. that fits comfortably and allow extra clearance for movement and for passing over fittings.

Use D = C ÷ 3.14. Example: C = 160 mm → D ≈ 51 mm. Keep units consistent (mm or inch).

Send your hose/bundle O.D., routing constraints, temperature range, and exposure type. We will confirm sleeve sizing and recommend the appropriate product family.