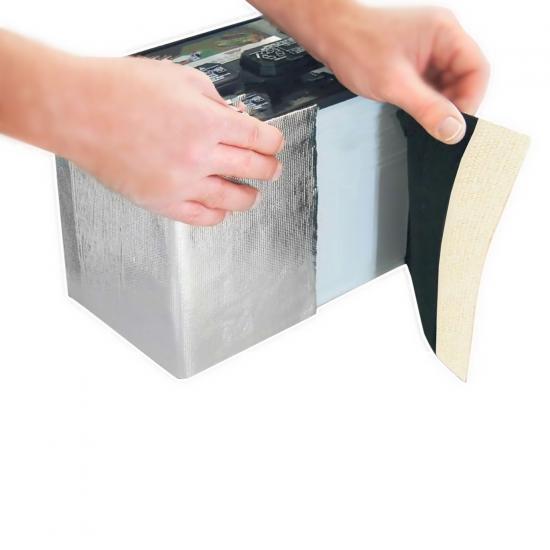

Battery Heat Shield Wrap (Acid-Absorbing Heat Barrier)

This battery heat shield wrap is a protective barrier designed for car battery heat shield and automotive battery heat shield applications where batteries are exposed to radiant heat, airflow heat soak, and potential splash/corrosion risks. It combines a heat barrier function to help reduce heat exposure with an acid-absorbing protection concept for battery zones where electrolyte or corrosive mist may be present.

Exhaust-side heat management: exhaust insulation solutions | Local barriers and tapes: heat shield tapes and barriers | Hose/wire protection near hot zones: fire sleeve protection | Technical PDFs: download technical documents

What is a battery heat shield wrap?

A battery heat shield wrap (also called heat shield for battery or battery heat barrier) is a protective covering installed around or near battery housings to reduce heat exposure from nearby sources. In vehicles, the most common heat sources include exhaust routing, turbo/manifold zones, and hot airflow paths. The goal is to reduce radiant heat transfer and heat soak that can accelerate aging of surrounding components.

Typical applications

- Car battery heat shield: battery area protection in engine bays and under-hood compartments

- Automotive battery heat shield: platforms with tight packaging and high underhood temperatures

- EV battery heat shield: localized thermal shielding around battery-related zones and adjacent heat sources (application-dependent)

- Battery barrier with corrosion risk: environments where electrolyte mist or splash may occur and additional protective behavior is desired

What this heat barrier helps you achieve

- Reduce radiant heat exposure: helps limit heat soak to battery zones and nearby components

- Improve reliability in tight packaging: supports thermal management where clearance is limited

- Support protective behavior against splash/corrosion risk: for battery zones where harsh exposure may exist

If the battery area is affected by a very hot source (exhaust pipe, catalyst, turbo/manifold zones), consider reducing heat at the source first using exhaust insulation solutions, then apply a battery heat shield wrap for adjacent protection.

Selection notes (engineering-style)

Heat mode: radiant vs near-contact

- Radiant heat dominant: reflective/insulating barriers perform best when an air gap can be maintained.

- Near-contact risk: treat near-contact as contact under vibration; secure mounting and edge control become critical.

Installation and retention

Performance depends on stable retention. Loose barriers can rub through or migrate during vibration. If the battery zone includes sharp brackets or clamp edges, plan edge protection and verify clearance after heat cycles.

Failure modes and how to prevent them

- Rub-through at edges/brackets: increase clearance where possible; validate mounting points.

- Barrier loosening/migration: improve retention and confirm after thermal cycling.

- Heat spots from direct contact: avoid contact with hot components; add spacing or upgrade structure.

RFQ-ready checklist (copy/paste)

- Vehicle type: car / truck / EV / hybrid / industrial equipment

- Battery zone: underhood / underbody / enclosure area

- Heat source nearby: exhaust / catalyst / manifold / hot airflow

- Clearance: minimum distance to hot source ____ mm / ____ inch

- Wrap size: length ____ , width ____ (photos/drawing recommended)

- Exposure: vibration / splash / dust / oil (yes/no)

- Quantity: prototype or production volume, target delivery date

FAQ

What is a battery heat shield wrap used for?

A battery heat shield wrap is used to reduce radiant heat exposure and heat soak in battery zones, helping protect nearby components and improve reliability where packaging is tight.

Is this a car battery heat shield or an EV battery heat shield?

It can be used for both. For car battery zones, it helps block radiant heat from nearby hot components. For EV platforms, it may be used for localized shielding near adjacent heat sources; share your layout and clearance for recommendation.

Do I need an air gap for best performance?

Yes. Most heat shields perform best when a stable air gap is maintained. If vibration may cause contact, treat it as contact heat and improve retention or structure.

Can you provide technical documents?

Yes. You can request datasheets and related documents via our inquiry form or check available files in download technical documents.

What information speeds up quotation?

Battery zone photos, nearby heat source, clearance, target dimensions, and expected exposure (vibration/splash) allow fast recommendation and accurate quotation.

Need a battery heat shield recommendation?

Send battery zone photos, heat source location, clearance, and target wrap size. We will recommend a suitable battery heat shield solution and provide technical documents if required.