Titanium Exhaust Wrap for High-Temperature Exhaust Systems

Titanium exhaust wrap is a high-performance thermal insulation material engineered to manage extreme exhaust heat in motorcycle, automotive, and high-performance engine applications. Designed for environments where conventional fiberglass wraps reach their limits, titanium exhaust wrap provides enhanced durability, superior thermal stability, and long-term resistance to heat cycling.

By reducing radiant heat from exhaust components, titanium exhaust wrap helps protect surrounding parts, improves thermal efficiency, and contributes to safer, more reliable exhaust system operation.

What Is Titanium Exhaust Wrap?

Titanium exhaust wrap is a premium exhaust insulation wrap manufactured from advanced high-temperature fibers, commonly based on titanium-enhanced basalt or lava fiber constructions. Unlike traditional fiberglass exhaust wrap, this material is designed to withstand higher continuous temperatures and repeated thermal cycles without rapid degradation.

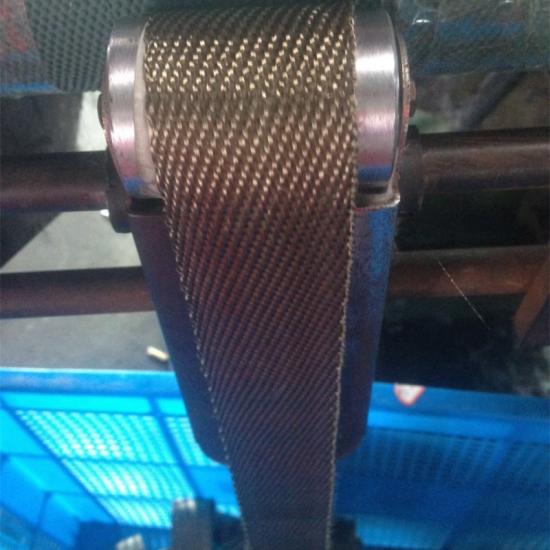

Its dense woven structure allows it to tightly conform to exhaust pipes, headers, and downpipes, forming an effective thermal barrier that minimizes heat transfer to nearby components.

Titanium exhaust wrap is widely adopted in motorcycle exhaust systems, turbocharged vehicles, racing applications, and performance-oriented builds where heat control is critical.

Material Composition and Construction

This titanium exhaust wrap is produced using high-strength mineral-based fibers engineered for elevated temperature environments. The fibers are tightly woven to create a compact structure that resists fraying, vibration damage, and thermal fatigue.

Key material characteristics include:

-

High-temperature resistant fiber composition suitable for extreme exhaust environments

-

Dense weaving for improved insulation efficiency and mechanical strength

-

Excellent resistance to heat cycling and long-term thermal exposure

-

Improved durability compared to standard fiberglass exhaust wraps

The material maintains structural integrity even when exposed to repeated heating and cooling cycles common in exhaust systems.

Thermal Performance and Heat Management

Titanium exhaust wrap is designed to perform reliably in demanding exhaust conditions where sustained and radiant heat levels are significantly higher than in standard applications.

Typical performance characteristics include:

-

Effective reduction of radiant heat from exhaust surfaces

-

Stable insulation performance under continuous high-temperature operation

-

Improved heat containment along exhaust pipes and headers

-

Reduced heat transfer to surrounding components and engine bay areas

By keeping exhaust heat contained, titanium exhaust wrap supports improved exhaust gas velocity and helps maintain consistent thermal conditions across the exhaust system.

Titanium Exhaust Wrap vs Fiberglass Exhaust Wrap

Compared to traditional fiberglass exhaust wrap, titanium exhaust wrap offers clear advantages in durability and long-term performance.

Fiberglass wraps are suitable for moderate heat levels but tend to degrade more quickly when exposed to extreme temperatures and frequent thermal cycling. Titanium exhaust wrap, by contrast, is engineered for higher temperature environments and provides improved resistance to fiber breakdown, surface embrittlement, and insulation loss over time.

For applications involving turbochargers, high-output engines, or continuous high-load operation, titanium exhaust wrap delivers more consistent performance and a longer service life.

Typical Applications

Titanium exhaust wrap is suitable for a wide range of exhaust heat management applications, including:

-

Motorcycle exhaust systems and headers

-

Turbocharger and downpipe insulation

-

Racing and high-performance vehicle exhausts

-

Off-road and powersports exhaust systems

-

Custom exhaust fabrication projects

Its flexibility allows it to conform easily to straight pipes, bends, and complex exhaust geometries.

Installation and Usage Guidelines

For optimal performance and service life, proper installation of titanium exhaust wrap is essential.

General installation recommendations include:

-

Wrap the exhaust pipe with consistent overlap, typically 25–50% of the wrap width

-

Secure the wrap using stainless steel ties or clamps

-

Lightly pre-wetting the wrap during installation can improve conformity and reduce airborne fibers

-

Allow the wrap to cure naturally during initial heat cycles

-

Ensure adequate ventilation during first heat-up, as minor smoke may occur during curing

Correct installation helps maximize thermal efficiency and extends the operational lifespan of the wrap.

Frequently Asked Questions

Does titanium exhaust wrap smoke during initial use?

Light smoke may occur during the first heat cycle as the wrap cures. This is normal and temporary.

How long does titanium exhaust wrap last?

When properly installed, titanium exhaust wrap typically lasts significantly longer than standard fiberglass wraps, even under high-temperature conditions.

Is titanium exhaust wrap better than fiberglass exhaust wrap?

For high-temperature and performance applications, titanium exhaust wrap offers improved durability, heat resistance, and long-term stability.

Can titanium exhaust wrap be used on turbo downpipes?

Yes. Titanium exhaust wrap is well suited for turbocharger and downpipe insulation due to its higher temperature tolerance.

Is it suitable for motorcycle exhaust systems?

Yes. Titanium exhaust wrap is commonly used on motorcycle exhausts to reduce surface temperature and improve rider safety.

Does exhaust wrap increase exhaust temperature?

Exhaust wrap helps retain heat within the exhaust flow, which can improve gas velocity while reducing external radiant heat.

Why Choose Titanium Exhaust Wrap

Titanium exhaust wrap is the preferred solution for applications where thermal performance, durability, and long-term reliability are critical. Its advanced material construction and proven heat management capabilities make it suitable for professional exhaust fabrication, performance tuning, and demanding industrial environments.

Technical Documentation

A technical overview document is available for engineers and technical buyers requiring material composition and thermal performance reference.

Titanium Exhaust Wrap – Technical Overview (PDF)