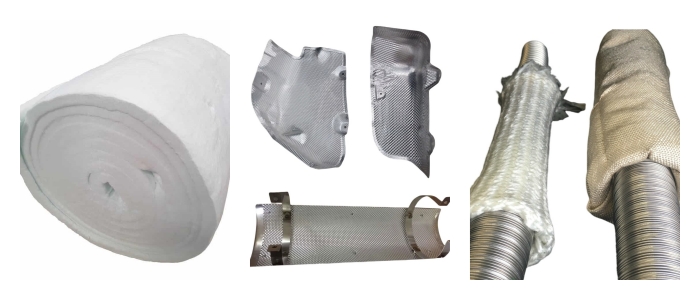

An exhaust insulator is a thermal protection product designed to reduce heat transfer from hot exhaust components into surrounding areas. In practice, exhaust insulation and exhaust pipe insulation solutions help control surface temperatures, reduce radiant heat, protect nearby hoses and wiring, and improve overall durability in automotive, industrial, and marine applications.

If you are comparing different exhaust insulation formats, start with our category hub: Exhaust Heat Shield Insulation.

When you want heat reduction but must maintain a clean stock appearance, a liner insert can be the best approach. It installs between the exhaust pipe and the outer shield to reduce heat transfer while staying hidden.

Manifolds and turbo hot-side areas create intense radiant heat. The best exhaust insulation in these zones must survive thermal cycling and vibration, and it must stay secured. Choose blanket-style insulation when clearance is tight and heat soak is damaging surrounding components.

Downpipes and catalyst-adjacent routing often sit close to wiring, hoses, and firewall/bulkhead areas. A contoured downpipe insulation blanket reduces radiant heat transfer and helps lower engine bay temperatures.

Elbows are common hot zones where exhaust routing changes direction and airflow/temperature gradients create concentrated heating. An elbow blanket can act as an exhaust insulator to reduce heat radiation and protect adjacent structures.

Thermal Insulation Elbow Blanket

Heat soaking into intake-side components reduces consistency and can stress nearby assemblies. A dedicated inlet pipe blanket helps stabilize temperatures around the inlet pipe and protects surrounding parts from radiant exposure.

For coverage across larger areas, heat shield kits are used to reflect and reduce thermal transfer through panels and tunnels. Depending on your design, kits may be selected with or without adhesive backing.

Aluminized Heat Control Heat Shield Kit

Diesel heater exhaust routing has a very clear search intent: users need burn protection and safer exhaust pipe routing. A fiberglass lagging sleeve is a common exhaust pipe insulation solution for this application.

An exhaust insulator reduces heat transfer from hot exhaust components to nearby parts by limiting radiant heat and, in some cases, conductive heat. The result is lower heat soak and improved durability for adjacent hoses, wiring, plastics, and panels.

No. Exhaust pipe insulation is used across passenger vehicles, heavy-duty equipment, industrial generators, and marine engines—especially where clearance is tight and sensitive components are nearby.

Use blankets for tight high-heat zones (manifold/downpipe/elbow), liners when you need hidden insulation inside an OEM shield, and shield kits when you need broader panel coverage and controlled installation.

Photos of the hot zone, clearance measurements, the component type (manifold/downpipe/elbow/heater pipe), and your preferred retention method. With this, we can recommend the right structure quickly.

Tell us your application zone and clearance, and share photos of the routing area. We’ll recommend the best exhaust insulator option and quote quickly.