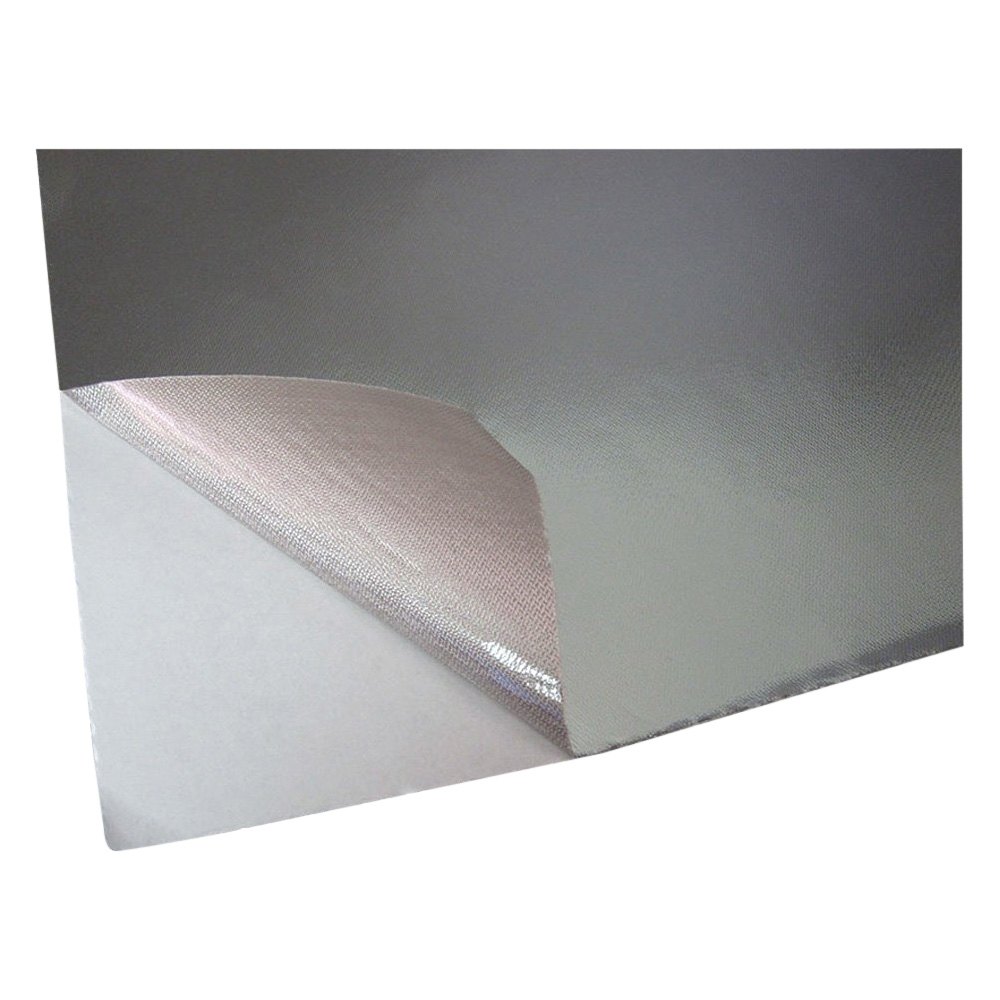

The applications for Adhesive-Backed Heat Shielding are as diverse and wide-ranging as the sources of heat themselves. Its unique combination of high-temperature resilience, effortless customizability, and simple peel-and-stick installation has made it an indispensable tool in industries and homes around the world, serving one primary purpose: to protect valuable equipment and structures from the damaging, costly, and often dangerous effects of excessive heat.

In the automotive and transportation sector, its uses are virtually limitless. Under the hood of cars, trucks, and motorcycles, temperatures can soar, threatening sensitive and expensive components. Adhesive-Backed Heat Shielding is routinely applied to the inside of the firewall to prevent engine heat from baking the occupants' feet and damaging the cabin's electronics. It is wrapped around wiring harnesses and fuel lines that run near exhaust headers or turbochargers, preventing the plastic and rubber from melting, cracking, or becoming brittle. RV owners use it to protect interior cabinetry and flooring from the intense heat generated by chassis components, while also applying it near onboard generators. In the world of performance and racing, enthusiasts custom-cut shapes to shield brake master cylinders, ECU units, and carbon fiber bodywork from radiant heat, ensuring peak performance and reliability. The key advantage here is the ability to install it "in-situ" – there is no need to remove the fender or disassemble the dashboard; simply clean the surface, cut the shield to shape, and apply it directly onto the component that needs protection.

The residential and commercial construction field has embraced this material for its ability to solve common and persistent heat-related issues. In the kitchen, walls situated adjacent to ovens, especially built-in models, are often subjected to constant, low-level heat that can eventually crack drywall, degrade paint, and even pose a fire risk. A precisely cut piece of heat shielding applied to the wall behind or beside the oven acts as a reflective barrier, preserving the wall's integrity. The same principle applies to areas around microwaves, refrigerators (particularly the condenser coils), and dishwashers. Beyond the kitchen, it is used to protect walls and floors behind wood-burning stoves and fireplace inserts, providing an extra layer of safety that goes beyond standard clearances. HVAC technicians use it to shield wooden floor joists and subfloors from hot air ducts, while it can also be applied to the underside of a roof to reflect solar radiant heat, contributing to lower attic temperatures and reduced cooling costs in the summer.

Venturing further, the electronics and manufacturing industries rely on it for critical thermal management. It is used to line enclosures for sensitive control units, programmable logic controllers (PLCs), and power supplies in industrial settings, reflecting external heat sources to maintain a stable internal operating temperature. It can be fashioned into custom shields for drones, protecting flight controllers and batteries from the heat of motors and ESCs (Electronic Speed Controllers). In marine applications, it protects boat hulls and internal structures from engine room heat.

The benefits of using Adhesive-Backed Heat Shielding translate directly into tangible value for the user. The most obvious is cost savings. By preventing heat damage, it eliminates the need for expensive repairs, such as replacing melted wiring harnesses, resurfacing scorched walls, or swapping out failed electronic components. This proactive protection is far more economical than reactive replacement. It also enhances safety by reducing the risk of fire and burns associated with overheated surfaces. The ease of application lowers labor costs and makes projects feasible for individuals of all skill levels, democratizing a level of thermal protection that was once the domain of specialized fabricators. Finally, its versatility means that a single, readily available product can serve as the solution for dozens of different problems in the garage, home, workshop, or factory, simplifying inventory and procurement.

From a high-performance race car to a family kitchen, from a commercial drone to a marine engine room, Adhesive-Backed Heat Shielding stands as a simple, yet profoundly effective, first line of defense against the relentless and destructive power of heat.