When it comes to protecting critical components from the damaging effects of high temperatures, exhaust heat shield insulation plays a pivotal role in a wide range of applications, from automotive to industrial machinery. Different materials are available for heat shielding, each with its unique benefits and trade-offs. Understanding the properties and performance of these materials is essential for making informed decisions based on specific needs, whether you're an engineer, vehicle manufacturer, or industrial procurement specialist.

In this article, we will compare some of the most commonly used materials in exhaust heat shield insulation: aluminized fiberglass, ceramic fiber, stainless steel, and embossed aluminum. Each material has its own set of advantages and is suited to different environmental and performance demands.

Overview:

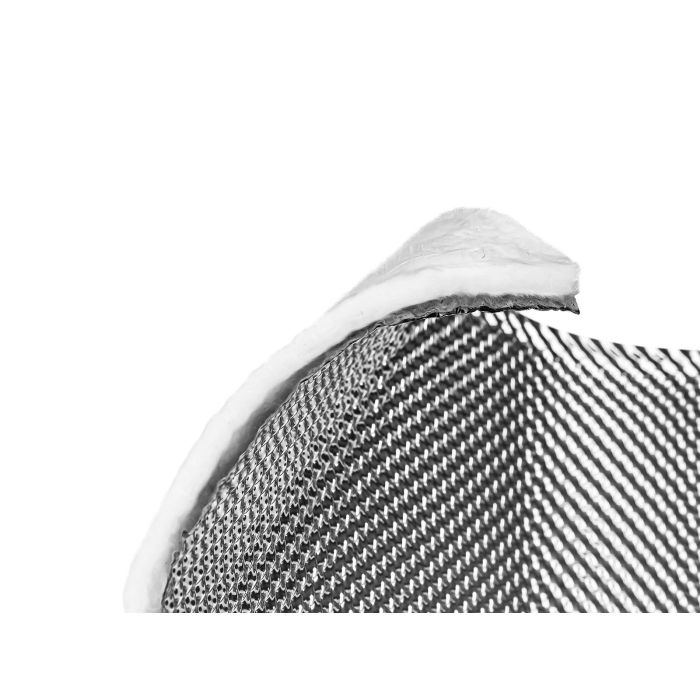

Aluminized fiberglass is one of the most widely used materials for exhaust heat shield insulation due to its combination of durability, flexibility, and high heat resistance. The material is made by coating fiberglass with a thin layer of aluminum. This process results in an insulation material that has excellent reflective properties, allowing it to reflect a significant amount of heat away from sensitive components.

Performance:

Temperature Resistance: Aluminized fiberglass can withstand temperatures up to 1200°F (650°C) continuously and up to 1800°F (982°C) for short durations.

Reflectivity: The aluminum coating reflects radiant heat, significantly reducing heat transfer to surrounding areas.

Flexibility: The material is flexible and can easily be formed into wraps, blankets, and shields for different exhaust system components.

Durability: Aluminized fiberglass is highly resistant to wear and abrasion, making it ideal for environments where mechanical stress or vibration is common.

Applications:

Automotive exhaust systems, including headers, turbochargers, and catalytic converters.

Motorcycles and racing vehicles.

Heavy-duty trucks and construction machinery.

Advantages:

Cost-effective compared to other high-performance insulation materials.

Excellent for reducing radiant heat and protecting nearby components such as hoses, wires, and fuel lines.

Limitations:

May not perform as well in extremely high-temperature applications compared to ceramic fiber.

The aluminum layer can degrade over time in environments with constant exposure to extreme heat and moisture.

Overview:

Ceramic fiber is a high-temperature-resistant material that offers exceptional thermal insulation. It is made from spun ceramic fibers that provide both heat resistance and low thermal conductivity, making it ideal for extreme environments. Ceramic fiber is typically used in the form of blankets, boards, or wraps for heavy-duty insulation applications.

Performance:

Temperature Resistance: Ceramic fiber can withstand temperatures of up to 2300°F (1260°C) continuously and even higher in short bursts.

Insulation Efficiency: Due to its low thermal conductivity, ceramic fiber provides excellent thermal insulation, keeping exhaust systems cooler and preventing heat damage to surrounding components.

Weight: It is lightweight, which is beneficial in applications where weight reduction is important, such as racing cars and motorcycles.

Chemical Resistance: Ceramic fiber is resistant to most chemicals, oils, and solvents, making it highly durable in challenging environments.

Applications:

Industrial furnaces and kilns.

Automotive exhaust systems, especially high-performance racing cars and turbocharged engines.

Marine engines and off-road equipment.

Advantages:

Extremely high-temperature resistance makes it ideal for extreme heat conditions.

Provides superior insulation efficiency in high-heat environments.

Limitations:

Can be brittle and fragile, especially when exposed to mechanical stress or impact.

Higher cost compared to aluminized fiberglass, making it more suited for high-end applications.

Overview:

Stainless steel is a durable and strong material that is often used in exhaust heat shields, especially in applications where mechanical protection is essential. Stainless steel is resistant to both heat and corrosion, which makes it an excellent choice for harsh industrial environments and vehicles exposed to a lot of wear and tear.

Performance:

Temperature Resistance: Stainless steel can withstand temperatures up to 1500°F (815°C) without compromising its structural integrity.

Durability: Stainless steel offers high resistance to mechanical stress, vibration, and corrosion. It can withstand physical damage better than softer materials like fiberglass or ceramic fiber.

Reflectivity: While stainless steel does reflect some heat, it is not as effective as aluminized fiberglass in terms of radiant heat reflection.

Applications:

High-performance vehicles, especially those involved in racing or extreme off-road conditions.

Industrial exhaust systems, such as those found in power plants or manufacturing facilities.

Marine engines and heavy-duty machinery.

Advantages:

Provides long-term durability and strength in high-stress environments.

Resistant to corrosion and physical wear, making it suitable for rugged industrial applications.

Limitations:

Does not provide as much heat reflection as materials like aluminized fiberglass or ceramic fiber.

Heavier than fiberglass or ceramic alternatives, which may not be ideal for weight-sensitive applications.

Overview:

Embossed aluminum is a lightweight, high-performance material commonly used in exhaust heat shields for automotive and industrial applications. It combines the reflective qualities of aluminum with additional surface texture to improve its durability and heat dissipation properties. The embossed surface also provides added rigidity, making it more resistant to impact and wear.

Performance:

Temperature Resistance: Embossed aluminum can withstand temperatures up to 1200°F (650°C) without losing its shape or integrity.

Reflectivity: The embossed texture enhances the reflective capabilities of the aluminum, improving its ability to deflect heat from the exhaust system.

Durability: While not as durable as stainless steel, embossed aluminum is still resistant to corrosion and can handle moderate mechanical stress.

Applications:

Automotive exhaust systems and turbochargers.

Industrial applications where heat shielding is needed in relatively moderate temperature environments.

Marine and off-road vehicles.

Advantages:

Lightweight, making it ideal for applications where weight reduction is important.

The embossed surface provides improved durability and heat resistance compared to plain aluminum.

Limitations:

Lower maximum temperature resistance compared to ceramic fiber and stainless steel.

Can be less durable than other materials under heavy mechanical stress.

Choosing the right exhaust heat shield insulation material depends on several factors, including temperature resistance, durability, weight, and the specific application requirements. Aluminized fiberglass is a cost-effective solution for many automotive and industrial applications, offering excellent heat reflection and flexibility. Ceramic fiber provides superior high-temperature resistance, making it ideal for performance and industrial settings where extreme temperatures are common. Stainless steel and embossed aluminum offer durability and mechanical protection, but they may not be as efficient in heat reflection.

Understanding the unique properties and applications of these materials is key to selecting the best heat shield insulation for your needs, ensuring both performance and protection in demanding environments.