In modern automotive engineering, managing heat is one of the most critical aspects of maintaining performance, safety, and durability. Excessive heat from the exhaust system can cause severe damage to surrounding components, reduce engine efficiency, and increase maintenance costs. This is where exhaust heat shield insulation plays a vital role — it acts as a barrier that minimizes radiant and conductive heat transfer, keeping engine compartments cooler and components protected.

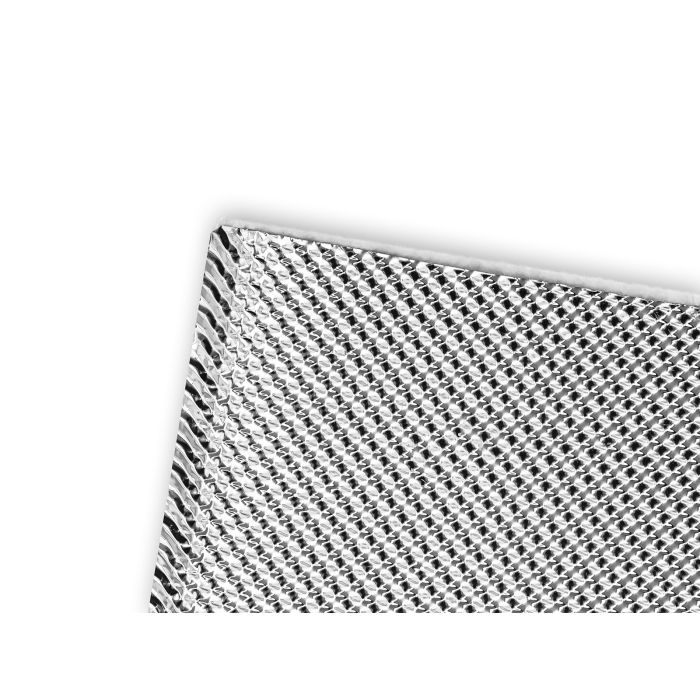

Exhaust heat shield insulation is a specialized thermal barrier designed to reflect and dissipate heat generated by the exhaust manifold, turbocharger, or downpipe. It typically consists of high-temperature materials such as aluminized fiberglass, ceramic fiber, or embossed metal composites. These materials resist continuous exposure to extreme heat while maintaining flexibility and strength, making them ideal for both automotive and industrial applications.

By insulating exhaust components, heat shield systems prevent heat from radiating into sensitive areas, such as wiring, fuel lines, and electronic sensors. This helps ensure the engine operates within its optimal temperature range, promoting efficiency and preventing heat-related malfunctions.

One of the key benefits of using exhaust heat shield insulation is improved engine performance and efficiency. When heat is contained within the exhaust system, it helps maintain higher exhaust gas temperatures, which in turn supports better exhaust flow and turbocharger response. A well-insulated exhaust system reduces thermal losses, allowing the engine to perform more consistently, even under demanding conditions.

Moreover, controlling ambient engine bay temperatures helps avoid heat soak, which can negatively affect air intake temperatures and power output. A cooler intake environment allows denser air to enter the combustion chamber, leading to improved fuel efficiency and more stable engine performance.

Uncontrolled heat radiation from exhaust systems can shorten the lifespan of surrounding components. Rubber hoses, plastic connectors, fuel lines, and electrical cables are all vulnerable to heat degradation. Exhaust heat shield insulation minimizes this risk by acting as a reliable thermal barrier.

In high-performance vehicles or off-road machines, where engine load and exhaust temperatures are higher than average, insulation becomes even more critical. Properly installed heat shields protect expensive components from cracking, melting, or premature failure. The result is a more reliable vehicle with lower maintenance requirements and longer service intervals.

In addition to protecting nearby components, exhaust heat shield insulation also helps maintain the exhaust system itself. It prevents rapid temperature fluctuations that can lead to material fatigue, corrosion, or cracking of exhaust pipes and manifolds. By stabilizing operating temperatures, insulation reduces thermal stress, extending the lifespan of metal components and improving long-term durability.

Exhaust heat shield insulation is used across a wide range of industries and vehicle types, including:

Automotive engines, motorcycles, and racing vehicles

Heavy-duty trucks and construction machinery

Marine engines and generators

Industrial exhaust systems and power equipment

Each application requires materials engineered for high thermal resistance, vibration tolerance, and environmental durability. For example, BSTFLEX offers custom-designed insulation solutions such as embossed aluminum shields, multi-layer composites, and flexible thermal wraps that meet the specific needs of both automotive and industrial customers.

Choosing the right exhaust heat shield insulation is not just about managing heat — it’s about improving overall engine performance, reliability, and longevity. By keeping heat under control, this essential component helps vehicles run more efficiently, protects valuable parts, and reduces the risk of costly damage.

For engineers, mechanics, and manufacturers looking to optimize performance in high-temperature environments, investing in high-quality exhaust heat shield insulation is a smart, long-term solution that delivers measurable results in both performance and durability.