Excessive heat can be one of the most damaging factors to vehicle and machinery performance, causing degradation, malfunction, and reducing the overall lifespan of critical components. For automotive and industrial applications alike, exhaust heat shield insulation serves as an essential solution to mitigate the impact of high temperatures on systems and structures. This comprehensive guide explores the materials, benefits, and various applications of exhaust heat shield insulation, equipping you with the knowledge to make informed decisions for your specific needs.

Exhaust heat shield insulation is a protective layer designed to reflect, absorb, and dissipate heat generated by exhaust systems. This specialized insulation helps prevent heat from radiating to nearby components, safeguarding them from heat damage. It is typically made from high-temperature-resistant materials like aluminized fiberglass, ceramic fibers, stainless steel, or embossed aluminum, and is available in a variety of forms including blankets, wraps, and shields.

This insulation is commonly used in both automotive and industrial sectors, where controlling heat is crucial for performance, safety, and durability.

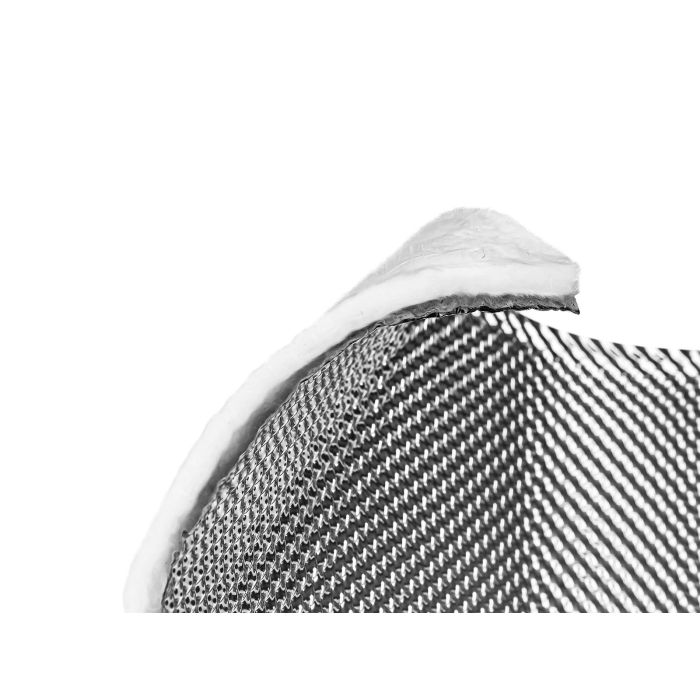

Aluminized Fiberglass

Aluminized fiberglass is a popular material used for exhaust heat shields due to its high resistance to heat and excellent durability. The material combines the insulating properties of fiberglass with a reflective aluminum surface, enhancing its ability to reflect heat while providing durability and flexibility. It is often used for automotive applications like exhaust pipes, manifolds, and turbochargers.

Ceramic Fiber

Ceramic fiber is a highly effective material that can withstand extremely high temperatures, often exceeding 2000°F (1093°C). It is used in industrial applications such as furnace linings, boiler insulation, and exhaust systems for heavy-duty trucks and machinery. Ceramic fiber is lightweight, non-combustible, and provides excellent thermal insulation properties.

Stainless Steel and Embossed Aluminum

For applications requiring durability and additional mechanical protection, embossed aluminum and stainless steel heat shields are often used. These materials are highly resistant to corrosion and are capable of withstanding mechanical stress, making them suitable for heavy-duty industrial machinery and high-performance vehicles.

Basalt and Other Natural Materials

In some industrial settings, natural basalt-based fibers are used for exhaust heat shields. These materials are heat-resistant and environmentally friendly, offering sustainable insulation solutions. They are commonly applied in sectors like manufacturing, power generation, and automotive industries where high-temperature resistance is necessary.

Exhaust systems are responsible for channeling the intense heat generated by the engine’s combustion process. However, this heat can cause nearby components — such as wiring, fuel lines, hoses, and sensors — to deteriorate over time. Exhaust heat shield insulation works by:

Reflecting Heat: Most modern heat shields feature a reflective aluminum or stainless-steel surface, which bounces heat away from sensitive parts, thereby reducing the amount of heat absorbed by surrounding components.

Absorbing Heat: Some insulation materials, such as ceramic fiber, are designed to absorb the heat and gradually dissipate it, keeping the immediate environment cooler.

Thermal Barrier: The insulation creates a physical barrier between the exhaust system and vulnerable components, acting as a shield against heat transfer.

By minimizing the transfer of heat, the insulation helps prevent overheating and heat-related damage, improving overall system performance.

Improved Engine Performance

The primary benefit of exhaust heat shield insulation is its ability to improve engine efficiency. By containing the heat within the exhaust system, it helps increase exhaust gas temperature, allowing for better exhaust flow and faster turbocharger spool times. This leads to improved power output and enhanced fuel efficiency.

Reduced Heat Damage to Components

Overheated components are prone to degradation, shortening their lifespan and increasing maintenance costs. Insulating the exhaust system reduces the risk of heat damage to components such as hoses, wires, and seals, preventing costly repairs and downtime.

Enhanced Safety

Insulating exhaust components helps prevent accidents caused by accidental contact with high-temperature surfaces. It reduces the risk of fires and thermal burns, making vehicles and machinery safer for operators and users.

Durability and Longevity

By protecting the exhaust system and surrounding components from excessive heat, heat shield insulation extends the lifespan of the vehicle or machinery. It prevents premature wear and tear caused by constant exposure to high temperatures, thus reducing the need for frequent repairs and replacements.

Lower Environmental Impact

As an additional benefit, many modern heat shield materials are recyclable and environmentally friendly. They offer an eco-conscious solution for industries looking to improve energy efficiency while reducing their carbon footprint.

Automotive and Performance Vehicles

In the automotive sector, exhaust heat shield insulation is used extensively in high-performance cars, motorcycles, and racing vehicles. The insulation helps optimize engine performance, protecting critical components such as fuel lines, electronics, and wiring from excessive heat. It's particularly beneficial in turbocharged engines, where controlling exhaust temperatures is essential for maintaining efficiency.

Heavy-Duty Trucks and Industrial Machinery

Large trucks, construction machinery, and industrial equipment are exposed to higher levels of heat. Exhaust heat shields are essential for protecting components in these high-temperature environments. From turbochargers to exhaust pipes, heat shield insulation ensures that critical parts remain safe and operational, even in the toughest conditions.

Marine Engines and Offshore Equipment

In marine applications, the harsh conditions of saltwater and extreme temperatures make exhaust heat shield insulation a must. Marine engines and exhaust systems rely on these products to prevent corrosion and heat damage, ensuring reliable operation in challenging environments.

Power Generation and Manufacturing

Exhaust heat shield insulation is vital in power plants, refineries, and manufacturing facilities where large-scale industrial equipment is used. By protecting exhaust systems and reducing heat loss, insulation helps increase energy efficiency, reduce emissions, and prolong the lifespan of critical infrastructure.

When selecting exhaust heat shield insulation for your application, it is essential to consider factors such as:

Temperature Rating: Ensure the insulation material can handle the temperatures produced by your exhaust system or engine.

Durability: Consider the material's resistance to corrosion, vibration, and physical wear.

Installation: Some insulation products require more complex installation methods, while others offer easy-to-use wraps or blankets that can be applied with minimal tools.

Application Environment: Whether you're working in an automotive, industrial, or marine setting, choose insulation that meets the specific needs of the environment, including resistance to water, oil, or other harsh conditions.

Exhaust heat shield insulation is a vital solution for managing heat in automotive and industrial applications. It improves engine performance, enhances safety, and extends the lifespan of components, making it an indispensable part of high-performance vehicles and heavy-duty machinery. By choosing the right insulation material and understanding its benefits, businesses and vehicle owners can ensure long-term reliability and performance.

If you're looking for custom exhaust heat shield insulation solutions tailored to your needs, BSTFLEX offers a wide range of high-quality thermal protection products that meet the demanding requirements of both automotive and industrial sectors.