What is the difference between SUS304 and SUS309 embossed stainless steel heat shield?

Jan 13,2025

The primary difference between SUS304 and SUS309 embossed stainless steel heat shields lies in their material composition, properties, and suitability for different heat resistance applications. Here’s a breakdown:

1. Material Composition:

-

SUS304: This is a commonly used stainless steel grade with 18% chromium and 8% nickel (also known as 18/8 stainless steel). It is widely known for its excellent corrosion resistance and ease of forming.

-

SUS309: This grade has a higher chromium content (22%) and nickel content (12%), which gives it superior heat resistance compared to SUS304. SUS309 is designed to withstand higher temperatures and is often used in environments where extreme heat resistance is critical.

2. Heat Resistance:

-

SUS304: It can withstand temperatures up to around 870°C (1,600°F) intermittently, but its performance decreases at higher temperatures.

-

SUS309: With its higher chromium and nickel content, SUS309 offers better heat resistance, tolerating temperatures up to 1,000°C (1,832°F) intermittently and can maintain its strength even at higher temperatures for extended periods.

3. Corrosion Resistance:

-

SUS304: Excellent general corrosion resistance, especially against atmospheric and mildly corrosive environments.

-

SUS309: Due to the higher chromium and nickel content, SUS309 provides superior corrosion resistance in high-temperature environments, particularly in acidic or highly corrosive atmospheres.

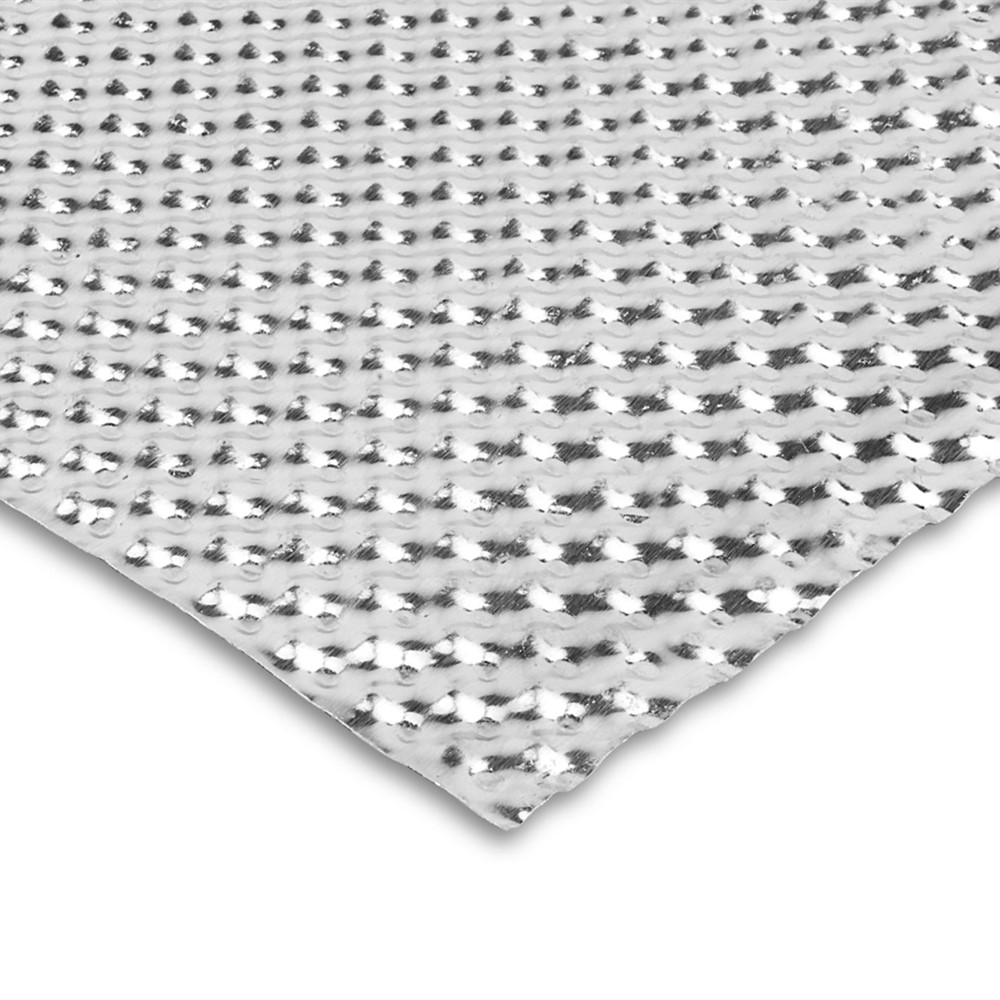

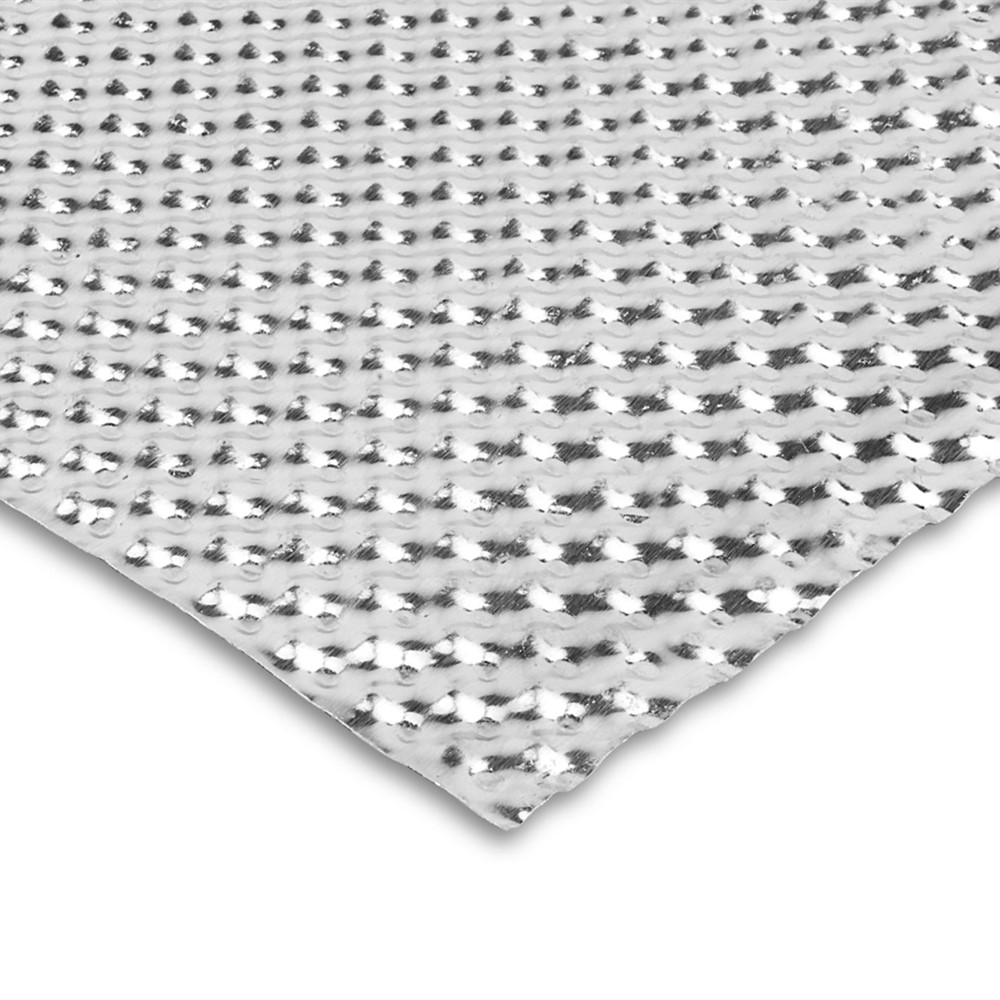

4. Embossing and Durability:

-

Both materials are typically used in embossed heat shields for enhanced strength, flexibility, and surface area, but SUS309 will generally offer better longevity and performance in extremely high-temperature applications compared to SUS304.

5. Applications:

-

SUS304: Used in general applications where heat resistance is important but not extreme, such as automotive heat shields, home appliances, and food equipment.

-

SUS309: More suitable for industrial applications requiring higher temperature resistance, such as furnaces, kilns, exhaust systems, and thermal protection systems exposed to extreme heat.

In summary:

-

SUS304 is excellent for general use with moderate heat resistance and corrosion protection.

-

SUS309 is a more specialized material for high-temperature applications, offering better heat resistance and durability at elevated temperatures.

If your heat shield needs to withstand more extreme heat (e.g., industrial furnaces, high-performance exhaust systems), SUS309 would be the better choice. For more standard or moderate applications, SUS304 would typically suffice.