An aluminum foil heat reflective sleeve can be highly effective in reducing heat damage by reflecting radiant heat away from the protected components. Here are some key points about its effectiveness:

Reflectivity: Aluminum foil has a high reflectivity, meaning it can reflect up to 95-98% of radiant heat. This makes it particularly effective in environments where heat radiation is a significant concern.

Thermal Insulation: The sleeve helps to create a barrier that reduces the amount of heat transferred to the protected components. This can be crucial for maintaining the integrity and performance of electrical wires, hoses, and other sensitive parts.

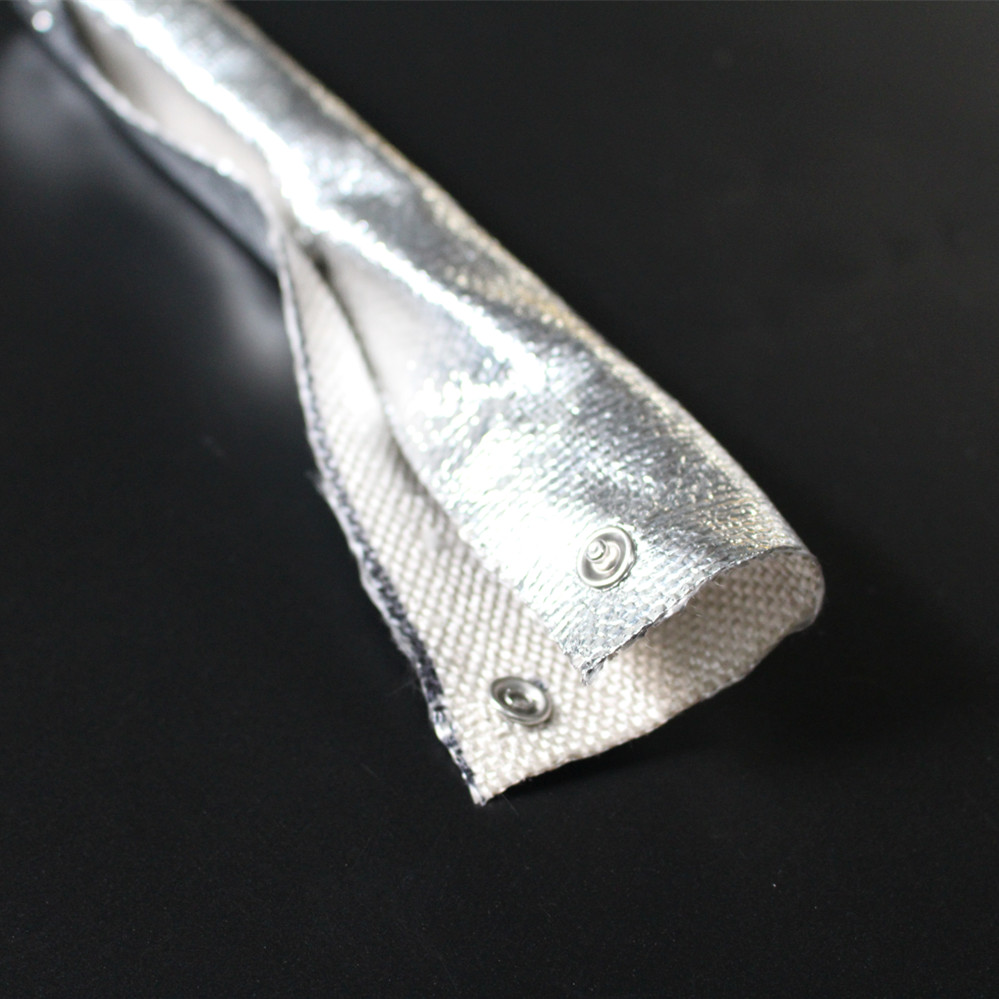

Durability: Aluminum foil sleeves are often combined with other materials, such as fiberglass or silicone, to enhance their durability and flexibility. This makes them suitable for use in demanding environments, such as automotive, aerospace, and industrial applications.

Versatility: These sleeves can be used in a wide range of applications, from automotive engines to industrial machinery, where they protect against heat damage and improve the lifespan of the components.

Easy Installation: Aluminum foil heat reflective sleeves are generally easy to install, often requiring no special tools. This makes them a practical solution for both new installations and retrofits.

Direct Contact: While effective against radiant heat, aluminum foil sleeves may not be as effective if they are in direct contact with a heat source. In such cases, additional insulation or protective measures may be required.

Mechanical Protection: Aluminum foil alone does not provide significant mechanical protection. If the sleeve is likely to be subjected to abrasion or impact, a reinforced version with an additional protective layer might be necessary.

Temperature Limits: The effectiveness of aluminum foil sleeves is also dependent on the temperature range. Ensure that the specific product used is rated for the temperatures it will be exposed to.

In summary, aluminum foil heat reflective sleeves can significantly reduce heat damage by reflecting radiant heat and providing thermal insulation. They are particularly effective in applications where radiant heat is a primary concern, but additional measures may be needed for direct contact with heat sources or mechanical protection.