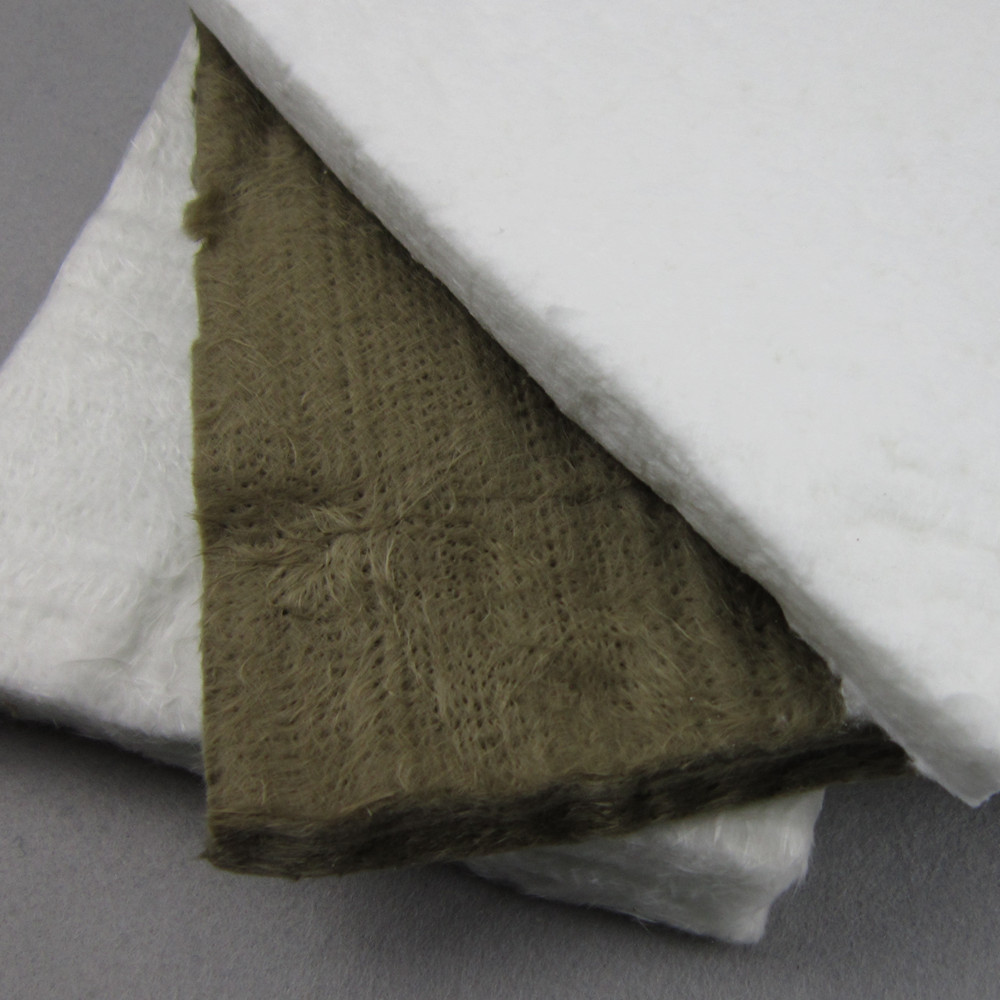

Silica needle mat is a highly efficient and durable thermal insulation material, specifically designed to withstand the extreme demands of industrial environments. Made from 99% pure silica fibers, this mat is widely recognized for its ability to enhance both efficiency and safety in industrial applications. Let’s explore how its unique properties make it an indispensable solution for various industries.

One of the primary advantages of silica needle mat is its excellent thermal insulation performance. With the ability to withstand continuous temperatures up to 1000°C (1832°F) and peak exposures as high as 1200°C (2192°F), the mat significantly reduces heat loss in industrial processes. This helps increase energy efficiency by:

In applications such as power generation, chemical processing, and metal refining, the efficient insulation provided by silica needle mat translates into reduced fuel costs and lower energy bills, contributing to overall operational cost savings.

In high-temperature industrial environments, safety is a critical concern. Silica needle mat provides a reliable thermal barrier, protecting workers and equipment from extreme heat exposure. Its excellent heat resistance helps reduce the risk of burns, equipment failure, and fire hazards in settings like:

By providing effective insulation, the mat helps to maintain safer working temperatures, protecting employees from dangerous heat exposure and ensuring compliance with safety regulations.

Silica needle mat has a low thermal conductivity, which means it efficiently prevents the transfer of heat between environments. This is particularly important for:

By maintaining stable temperatures and preventing thermal leakage, the mat ensures more controlled and efficient operations, reducing the risk of overheating and improving process reliability. It also helps reduce cooling costs by maintaining the desired temperature within specific equipment zones.

In addition to its thermal insulation capabilities, silica needle mat also offers sound absorption benefits, making it highly effective in noisy industrial environments. Its structure dampens sound waves, reducing noise levels in areas such as:

This dual-function capability improves the overall work environment by reducing noise pollution and enhancing comfort and safety for workers, while also complying with noise control regulations.

Industrial processes often involve exposure to chemicals, corrosive environments, and mechanical wear and tear. Silica needle mat’s high chemical resistance makes it an ideal solution for insulation in:

Its resistance to acids, alkalis, and other chemicals ensures long-lasting protection in harsh environments, reducing the frequency of replacements and minimizing downtime for maintenance. Furthermore, its durability and resistance to abrasion make it suitable for applications where mechanical stress is a concern.

Despite its excellent performance under extreme conditions, silica needle mat is lightweight and flexible, allowing for easy handling and installation. This flexibility is especially beneficial in applications with complex geometries or tight spaces, such as:

Easy installation reduces labor costs and downtime during maintenance, contributing to overall operational efficiency.

Silica needle mat is made from naturally occurring, non-toxic silica fibers, making it an environmentally responsible choice for industries looking to reduce their environmental impact. It is free of harmful substances and produces minimal emissions during its lifecycle, ensuring a safer and cleaner insulation solution.

Silica needle mat is an essential component for enhancing both efficiency and safety in industrial applications. Its superior thermal resistance, low thermal conductivity, sound absorption, chemical durability, and easy installation make it a cost-effective solution for industries ranging from power generation and petrochemicals to metal processing and manufacturing. By choosing silica needle mat, industrial operators can optimize energy usage, protect equipment and workers, and improve the overall safety and sustainability of their operations.