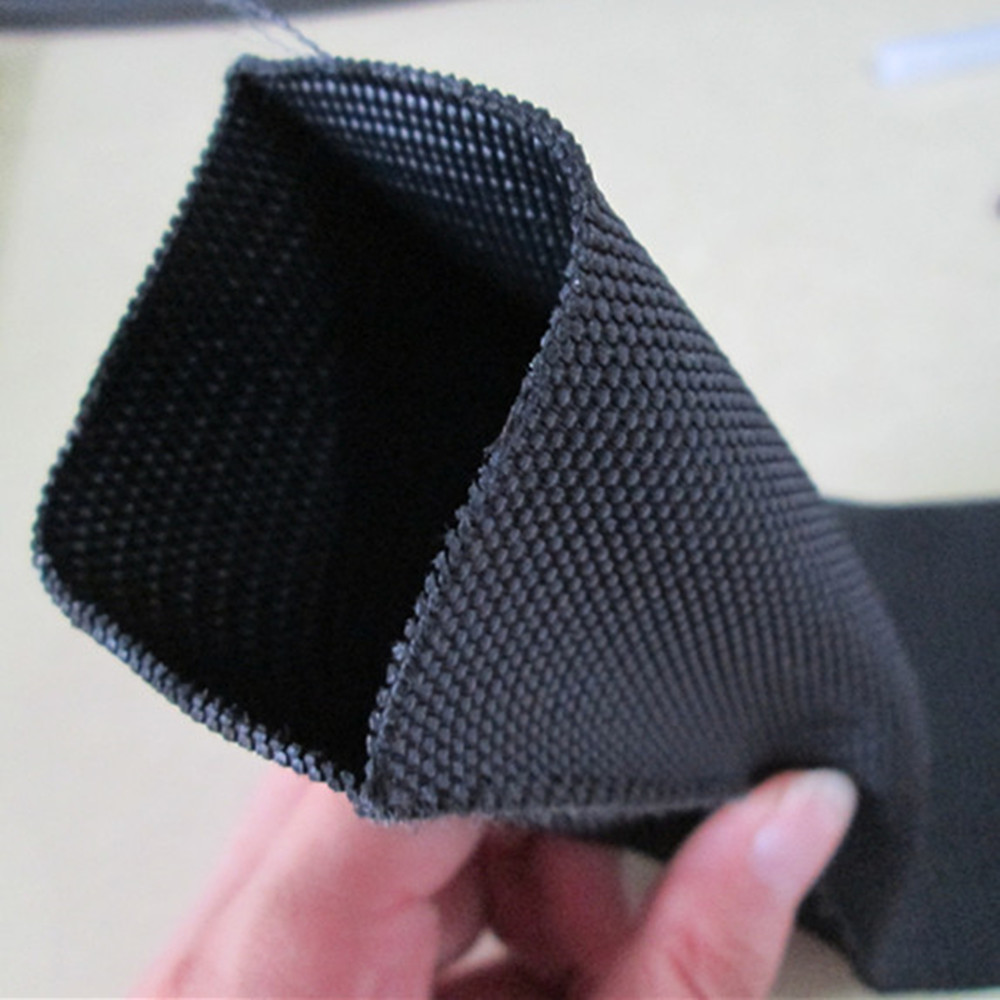

Nylon textile sleeves are highly effective at protecting hoses, cables, and wires in demanding environments. Here’s an understanding of how they work and their benefits:

How Nylon Textile Sleeves Work

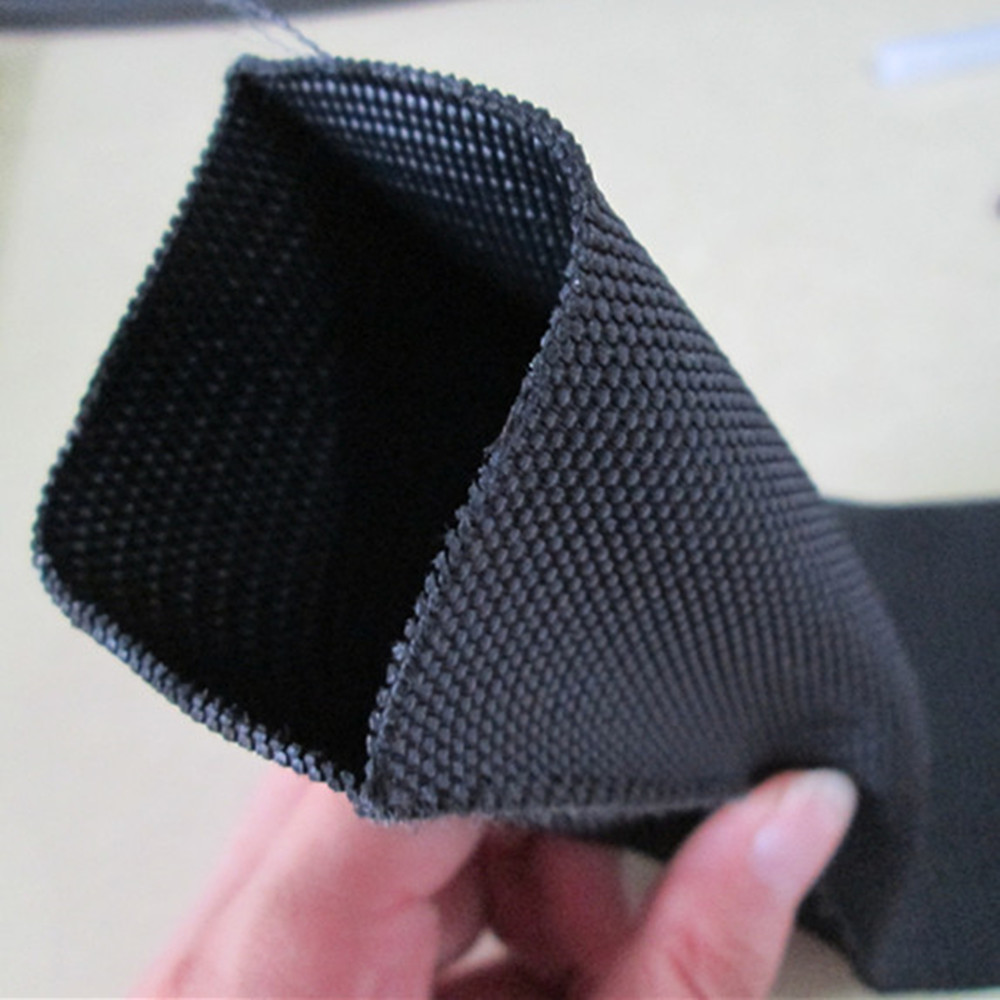

Nylon sleeves provide abrasion, impact, and chemical resistance by covering and safeguarding hoses, wires, and other sensitive components. Their flexible, tightly woven structure creates a barrier that shields from harsh conditions without restricting movement.

Key Benefits of Nylon Textile Sleeves

-

Abrasion Resistance: Nylon sleeves are highly resistant to friction and wear, prolonging the life of the components they protect.

-

Chemical and UV Resistance: These sleeves resist exposure to various chemicals, oils, and ultraviolet rays, making them ideal for outdoor and industrial settings.

-

Thermal Protection: While not designed for extreme heat, nylon offers moderate heat resistance, keeping components cool and preventing thermal damage.

-

Impact Protection: The woven nylon construction absorbs shocks and impacts, protecting hoses and cables from physical damage in harsh environments.

-

Flexibility: Despite their strength, nylon sleeves are lightweight and flexible, allowing easy installation and movement.

-

Noise Reduction: Nylon sleeves can help reduce noise caused by friction or vibration between hoses and other surfaces.

Applications

Nylon textile sleeve is commonly used in automotive, marine, and industrial sectors, where durability, flexibility, and environmental protection are essential. They are especially beneficial in hydraulic systems, cable assemblies, and equipment exposed to tough working conditions.

In summary, nylon textile sleeves offer a reliable, cost-effective solution for protecting critical components in rugged environments.